Help, My Hazmat Has 2 Hazards!

Some hazardous materials are hazardous in more than one way. A liquid might exhibit a flash point in the flammable range (Class 3) and a pH level that makes it corrosive (Class 8), for example.

For shippers, materials that fit the criteria for two or more hazard classes can be tricky to classify. When a material has more than one hazard, the shipper must determine which is the “primary hazard” and which is or are “subsidiary” (i.e., secondary) hazards.

Determining the primary hazard is a major part of the classification process that affects the shipper's next steps—from choosing a name to selecting packaging, labels and markings, shipping papers, and placards.

DOT Regulations for Precedence of Hazard (49 CFR 173.2a)

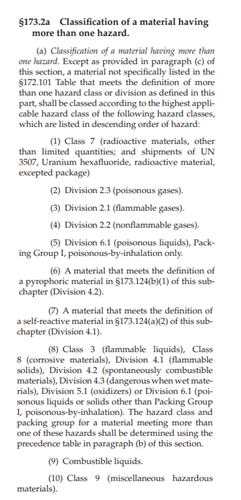

The instructions for determining precedence of hazard are found in 49 CFR 173.2a. Three paragraphs make up this subsection of the regulations—a, b, and c. Before we get to steps for deciding a primary hazard, let's peek at what's in each paragraph:

Paragraph (a) gives us a precedence of hazard list that ranks most (but not all) of the hazard classes and divisions 1—9. The class or division listed higher is always the primary hazard.

Paragraph (a) gives us a precedence of hazard list that ranks most (but not all) of the hazard classes and divisions 1—9. The class or division listed higher is always the primary hazard.

That seems simple enough—except for item #8, which is a doozy. We’ll come back to #8 later. (List pictured at right. Click to enlarge.)

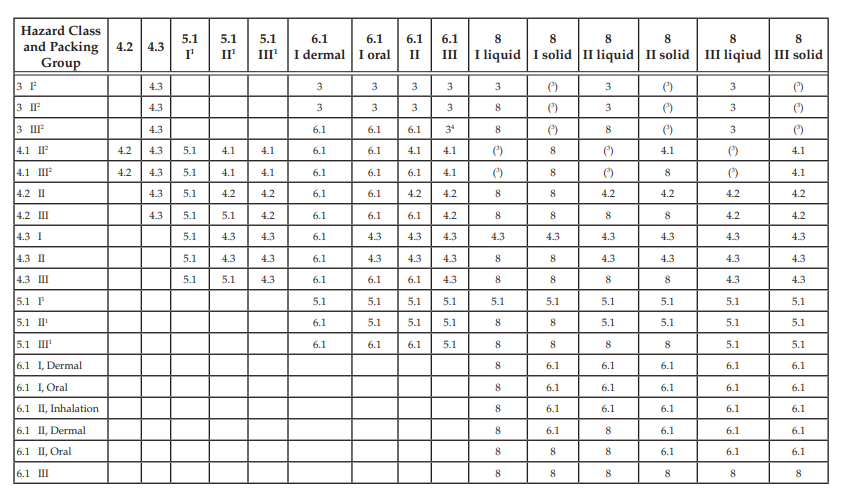

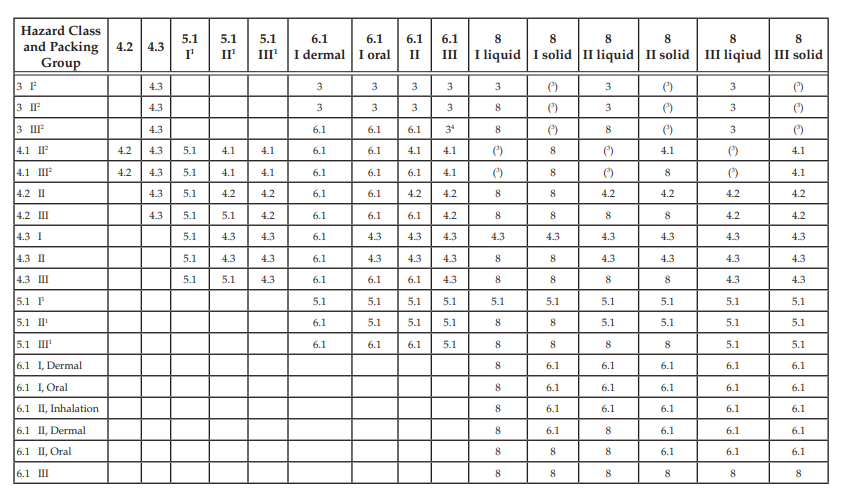

Paragraph (b) is a complex-seeming table or matrix with many numbers on it. This table is used to compare the hazards listed together in list item #8 in paragraph (a). (Table pictured below. Click to enlarge.)

.png?width=379&height=225)

Paragraph (c) lists five special cases that the rules/ranking in paragraph (a) above do not cover or apply to. We are going discuss those five special cases in Step 1, next.

How to Determine Precedence of Hazard

Given any material with two or more hazards, we can determine which hazard is the primary hazard and which is/are the subsidiary hazard(s) using the steps below to apply the text of 49 CFR 173.2a.

Step 1: Skip straight to paragraph (c)

Why start at paragraph (c)? 49 CFR 173.2a(c) gives us the list of special cases that are not subject to the rules in paragraph (a). If our material is one of these special cases, we want to know that now—instead of after we struggle with the other rules.

If your material is one of the following, you follow the rules in paragraph (c) to determine the primary hazard:

- Class 1 (Explosive)

- Division 5.2 (Organic peroxide)

- Division 6.2 (Infectious substance)

- Wetted explosives, as defined in 173.124(a)(1) (Division 4.1)

- A limited quantity of a radioactive material (Class 7)

If your hazmat has two or more hazards and one of them is Class 1 (explosive), Division 5.2 (organic peroxide), or Division 6.2 (infectious substance), then that is your primary hazard class. If you are shipping wetted explosives or a limited quantity of radioactive material, you follow special requirements for classification and/or approval from DOT.

Step 2: Check the precedence of hazard list in paragraph (a)

If our material is not a special case addressed in paragraph (c), we look to the precedence of hazard list in paragraph (a) to see how DOT ranks the hazard classes and divisions listed there.

To ship a material with more than one hazard, the shipper must review this list to see which class or division appears highest. The highest-ranked hazard class or division is our primary hazard, and the rest are subsidiary.

The list is simple enough, except for #8, which lumps together a laundry list of hazard classes, divisions, and packing groups and puts them all on equal footing..

49 CFR 173.2a(a)(8) reads:

"(8) Class 3 (flammable liquids), Class 8 (corrosive materials), Division 4.1 (flammable solids), Division 4.2 spontaneously combustible materials), Division 4.3 (dangerous when wet materials), Division 5.1 (oxidizers), or Division 6.1 (poisonous liquids or solids other than packing Group I, poisonous-by- inhalation).

The hazard class and packing group for a material meeting more than one of these hazards shall be determined using the precedence of hazard table in paragraph (b) of this section."

Like it says, if our material has two or more of the hazards listed together in (a)(8), then we will use the table in paragraph (b) to determine our primary hazard. Which brings us to Step 3.

Step 3: Using the precedence of hazard table in 49 CFR 173.2a(b)

The precedence of hazard table looks intimidating, but is easy to use when you approach it with two specific hazard classes or divisions in mind.

The vertical axis of the table lists all of the hazard classes/divisions from (a)(8) above, separated by Packing Group (PG). The horizontal axis lists most of them, with select classes/divisions removed to prevent redundancy in the table.To determine a "primary" between any two hazard classes or divisions:

- Locate the lower-numbered hazard on the horizontal axis

- Scan across to column that corresponds to the higher-numbered hazard

- The class or division listed at the intersection is the primary hazard class

If the box you arrive at has an asterisk (*) in it, you will refer to one of the notes below the table for instructions about what to do.

The precedence of hazard table [49 CFR 173.2a(b)].png?width=680&height=402)

Choosing the Right Packing Group (PG)

When comparing two or more hazard classes or divisions to determine the primary hazard, shippers must always retain the most stringent Packing Group among them.

For example: If our material is a Class 3, PG II and a Division 6.1, PG I, it will be classed as a Class 3, PG I. We can use the precedence of hazard table to see that "3, PG II" beats out the "6.1, PG I" as the primary hazard.

And, we keep the PG I associated with our 6.1 subsidiary hazard. Assigning the highest PG to the material ensures, for one thing, that an adequately rated UN packaging is used (i.e., X, Y, or Z).

Pro Tip: 3 or More Classes/Division (“The Battle Royale”)

You may have a hazardous material that fits the criteria for three or more hazard classes/divisions.

In this case, you will “battle” the hazard classes against each other, round robin style. You can run these head-to-head matchups in any order you want, and always get the same result or “winner.”

Unlike a playoff in sports, the winners and losers here are based on the text of the regulations—not on luck, skill, or desire. Use the steps above to compare any three classes/divisions, in any order, and you will see that the same one comes out on top every time. Go ahead, test it out!

For training to ship hazardous materials by ground, air, or ocean in full compliance with US and international regulations, visit Lion.com/Hazmat.

Tags: hazardous materials, hazmat classification, HMR, precedence of hazard

News and insights delivered to your inbox weekly.

View our Terms and Privacy Policy.

Find a Post

Recent Posts

Compliance Archives

Download Our Latest Whitepaper

Spot and correct 4 of the most common universal waste errors before they result in a notice of violation during a Federal or state inspection.

By submitting your phone number, you agree to receive recurring marketing and training text messages. Consent to receive text messages is not required for any purchases. Text STOP at any time to cancel. Message and data rates may apply. View our Terms & Conditions and Privacy Policy.